For the past several years a buzz has been growing in the security industry, this buzz can be found at tradeshows, in magazines, and just about everywhere in security. The buzz is centered on an acronym which has captured the attention of security professionals in many related industries, except one, corrections. That acronym is PSIM, or Physical Security Information Management.

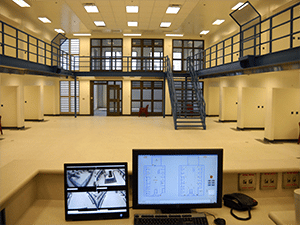

The idea of Physical Security Information Management (PSIM) was established around 2005 and was based on a similar acronym from the IT world, SIM, Security Information Management. While PSIM did not catch on until about 2007 for being an “all-in-one integration tool” for all of your security needs, in corrections this had already been done this since the 1980s. For an industry that is always considered to be so far behind and technically underdeveloped, corrections has been integrating all of their various security electronics for well over 30 years. In fact, the systems designed by us for the last 25 years in justice and corrections typify successful computer integration on many levels.

Not only has the corrections market been integrating their systems, but they have also been incorporating incident management and reporting into their integrated security systems as well, which is a highly desirable feature of many PSIM products. There are some differences though. While a PSIM is a software-based platform running on a server and integrating the various security system components through Application Programming Interfaces (APIs), the corrections market often integrates through a hardware-based Programmable Logic Controller (PLC). In both instances, there is a software layer sitting on top which produces a Graphic User Interface/Human Machine Interface for the user.

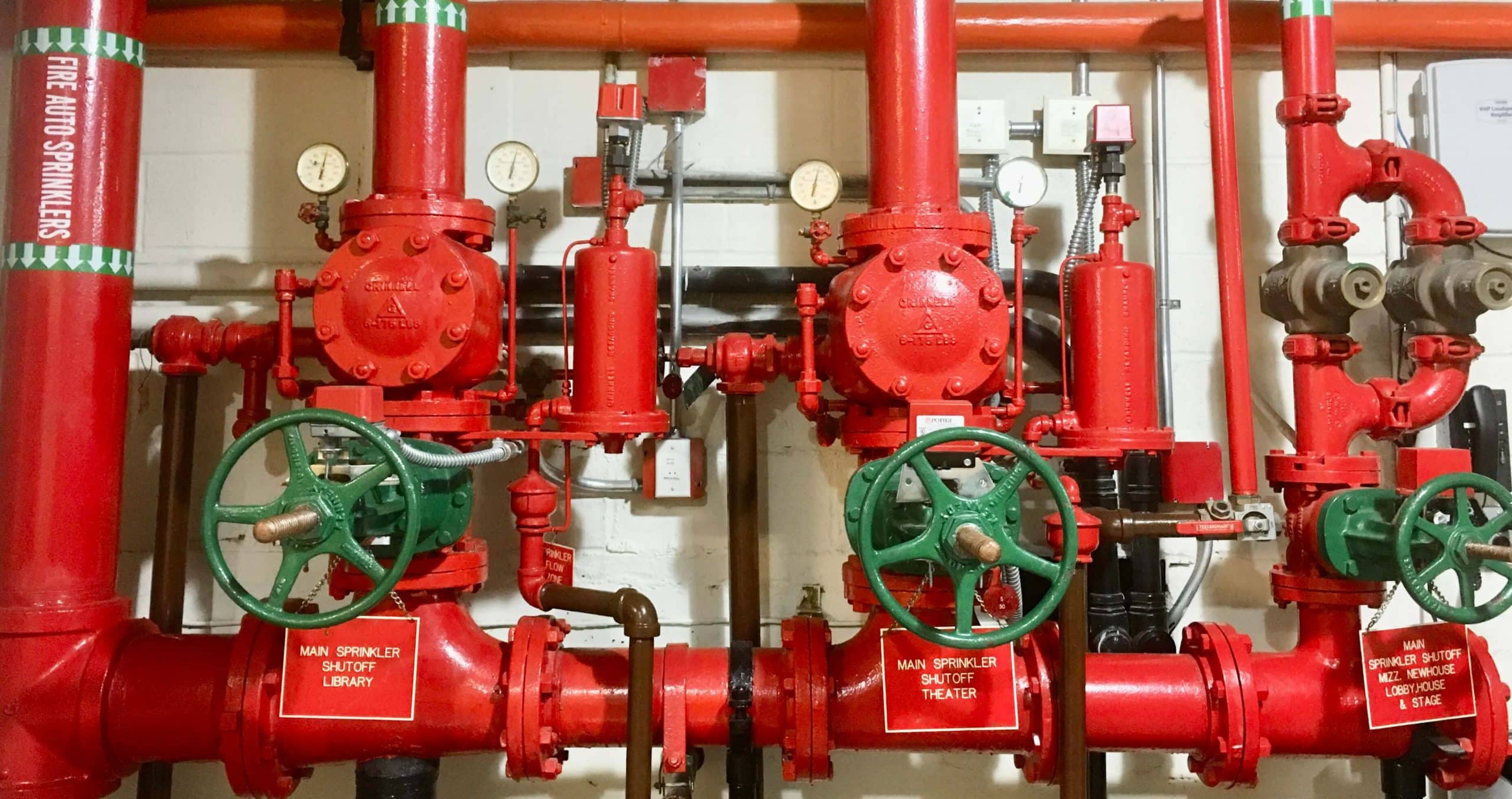

Traditionally, the PLC’s interface to the electronic security system is completed through a serial or Ethernet connection to the devices over a secure network. This allows for a single PLC-based electronic security system to communicate with most any technology from any manufacturer. Given that PLCs have been used in this role for decades, it has become a booming industry with many contractors specifically serving only the correctional market. The benefit is that the PLC communicates both independently and directly with the headend of however many systems it is connected with, be it video surveillance system, intercom/paging, perimeter intrusion detection system, fire alarm system, or anything else. This makes reliability and redundancy of core independent systems a great marriage.

Conversely, a PSIM communicates with its various connected systems through a software API interface over a secure network to the PSIM headend. Unfortunately, because it is not a direct hardware connection, sometimes the PSIM model suffers when manufacturers update their drivers, firmware, or software for their cameras, intercom systems, fire alarm panels, or various other systems by breaking the API connectivity between the PSIM and the devices it is connecting with, even if it is a simple patch or new license. Our consultants can verify, quantify, analyze, and evaluate the condition and lifetime expectancy of systems including NT server architecture, distributed Windows platforms, ’98-based GUI workstation controls, GE Fanuc, Omron, Allen Bradley, Rockwell, and even proprietary “brick” controls.

The major difference between the two systems is their interface with the connected field devices for means of controlling and establishing connected routines and outputting them graphically to a computer workstation. The PLC control system will utilize ladder logic-type programming, which is coded through a SCADA/HMI software platform to determine object relationships and provide graphic maps, reporting, and all of the necessary functions of an electronic security control system. An example would be camera 143 connected to door 12A. When door 12A is held open for 20 seconds, we’ll program the PLC to issue an alarm and call up camera 143. While this is not how the actual programming looks, it is the premise for the logic behind it. Instead of developing this hard “list” approach as a software instruction set, most PSIMs utilize dynamic geospatial mapping to associate specific devices. This allows the PSIM to know the coordinates of a door and associate any cameras within a given distance to the door with that door. So, in a common PSIM, you would locate the door on a geospatially referenced map, even if it is a building, and associate the nearest cameras with the door and indicate through the software when the cameras would be called up on a monitor.

While the two systems have inherent differences, especially in the way they are interconnected to devices and programmed, they are very similar in their function and usage. So, will we see future correctional facilities move to PSIM installations over PLC? Maybe someday, but the same could be said for PSIM customers. Most likely, we will see PSIM providers working more with PLC installations allowing their software to function as SCADA/HMI interface for the PLC or even hybrid applications such as one we’re currently developing. At present, the installation of a PSIM still requires the base SCADA/HMI interface in order to communicate. This is how PSIMs function; they ride on top of other manufacturer’s software and communicate the necessary information to a single interface.

PSE provides assessments and supports designs of both system integration types. Each has their benefits for the facilities/areas they serve. The use of either of these systems depends upon the needs of the end-user and how they need their system to be interfaced, maintained, and utilized. Other areas of usage may not require the level of integration that these two systems offer. A video management system or access control system could offer a more simple level of integration of systems and may be all that’s required.

And here’s where a consultant pays for themselves outright. Understanding the cost model associated with licensing, API development, and software support – costing as much as system capital costs in five years if not contracted properly.

So here’s where the two applications apply in the security space today. If you are interested in highly secure, mission critical control and integration while dealing with fixed in-place infrastructure like buildings or a campus that will seldom change, a PLC-based integration is recommended.

If, on the other hand, a large geospatially referenced site is the asset being protected with predicted improvements of various communications, safety, security, infrastructure, and systems that may not even be today anticipated – a PSIM is best.

While the corrections market may have done electronic security integration first, other companies, integrators, and software developers are constantly improving and providing new ways to allow the security industry to monitor, alert, and respond to the threats they face. PSE has a significant advantage having had the chance to work with many system providers offering real competition and innovation beyond what has traditionally been seen. The corrections industry has been an innovative leader in the development of mission critical security technologies and applications. You just don’t get to see it.